HVAC & Airflow Engineering

Precision is key in cleanroom design. Airflow rates for pressurized environments demand careful consideration. New facilities should prioritize application needs, air change rates, and specific safety/fume handling requirements.

HVAC Engineering for Projects of Any Size or Complexity

Evaluating criteria for air change design in cleanroom/contamination control systems is a daunting task, especially when modeling the dynamic operation of spaces. Potentially, each partition in the space typically requires specific Air Changes Per Hour (ACPH). and cascading differential pressure values to achieve ISO-rated certification.

Terra has pioneered several modern strategies to improve overall efficiency and performance in cleanroom systems.

Recirculating Airflow Cleanrooms: Recirculated air cleanroom systems are far more efficient than their 'Once-Through' counterparts because the recirculated air is preconditioned to the appropriate humidity and temperature values. As a result, recirculating HVAC designs are more precise and efficient, and can achieve more precise temperature and humidity setpoints with less energy demand.

Controlled Entry/Exit/Transfer: Ensuring uniform temperature and humidity throughout the cleanroom becomes more challenging when production requires frequent entry and exit of people and products. Areas that are closer to air entrances and exits have significant fluctuations in temperature and humidity. When two rooms of divergent pressure share the same wall, implementing transfer systems for products and people is necessary to maintain reliable temperature or humidity levels.

Cascading Airflow Design: Pressure design in controlled environments is a significant factor in controlling internal temperature and humidity values. It's important to design airflow patterns in a way that prevents the intermixing of clean, temperature controlled from outside spaces.

Self-Contained Cleanroom HVAC Systems: To ensure adequate space for manufacturing systems/equipment as well as parallel HVAC for the cleanroom systems, our cleanroom environments can be designed independently from the others, and minimize the disruption of ongoing operations in the other spaces or cleanrooms.

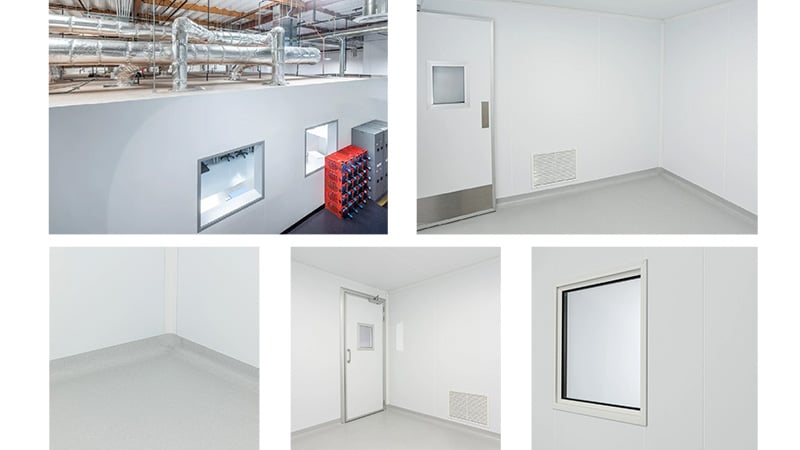

Modular Hardwall

Terra’s hardwall modular cleanrooms provide an enclosed, rigid freestanding structure with excellent pressure control capability

Traditional Stick-Built

Built-to-order designs for life science applications, such as biopharmaceutical applications that require a clean, sterile environment

BioSafe® Hybrid Modular

Prefab coving panels, modular assembly, and stick-built aesthetics. Hermetically sealed wall-to-floor and wall-to-ceiling conversions

Specialty Cleanrooms

NFPA-rated explosion-proof, particle containment, insulated temperature control, and fire-rated cleanroom designs

Nationwide Coverage

Terra employs designers, architects, and engineers to ensure alignment of aesthetic appeal, facility integration, and floor planning with respect to multi-functional spaces, while prioritizing efficiency and adaptability to meet evolving needs.

Globally Honored Pricing

Terra's network encompasses 20 global sales regions and 80 major suppliers with a wide range of global shipping options. Get door-to-door international delivery for brands such as Labconco, Thermo Fisher, Metro, Germfree, and Biofit.

Energy Optimization and Performance

Most pharmaceutical entities deploy aggressive internal strategies that require year-over-year improvements for energy expenditure initiatives. To put this task in perspective, several factors affect the final efficiency and performance of the final system as a whole:

- Increased airflow quantity requirements

- Increased ventilation requirements

- Increased filtration requirements

- Tighter tolerances for environmental controls (temperature & humidity)

This leads to a pivotal question in the quest for energy optimization and performance: Do facilities achieving best-in-class efficiency (75th percentile or higher when calculating Energy Performance Indicators [EPI] reflect superior energy management practices, or are they merely benefiting from more precise design qualifications that are tailored to their specific process requirements? Chances are, it's a mixture of both.

Terra orchestrates full-service cleanroom solutions along with their associated air-handling and filtration systems. Terra's customers benefit from substantial improvements in design methodologies, which stem from insights gleaned in high-performance ISO 5 - ISO 7 cleanroom builds for pharmaceutical, semiconductor, and biotech industries.

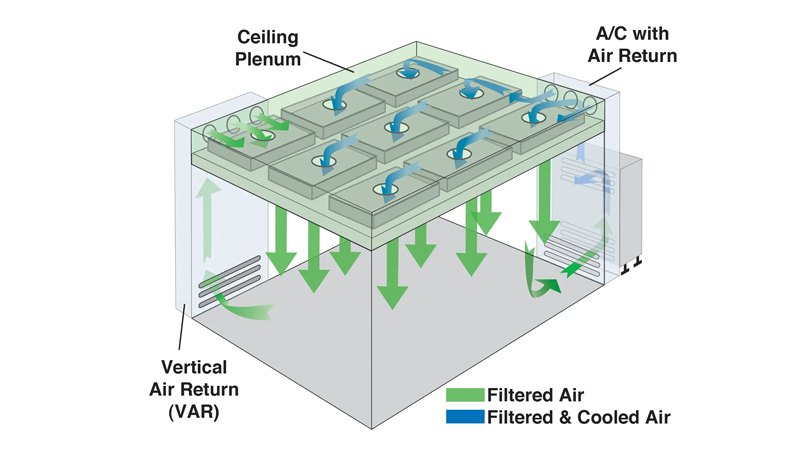

Vertical Air Returns for Cleanrooms: Terra's modular cleanroom designs are commonly specified with internally recirculating airflow patterns that dramatically improve heating and cooling efficiency when recirculating large volumes of pre-treated, HEPA-filtered air. Air return columns are crucial for maintaining tight temperature and humidity tolerances, thus dramatically reducing variability compared to single-pass systems, also referred to as "once through' cleanrooms. Typically, these vertical air returns are integrated into comprehensive cleanroom solutions rather than offered as standalone components.

Custom Air Shower Design & Installation: Air showers and tunnels consist of an enclosed chamber with high-velocity jets of filtered air that blow over personnel and materials entering the cleanroom or controlled environment. This efficient and effective process removes any loose particles from their clothing or surface before entering the cleanroom or controlled environment, ensuring a contaminant-free environment. Terra's air showers and tunnels are designed for easy installation and maintenance, making them a cost-effective solution for maintaining a clean environment.

Insulated Wall Panels: Well-insulated spaces retain heated or cooled air more efficiently, thus reducing total BTU requirements. The ease and simplicity of modular panel assembly allow for facilities to construct insulated, standalone enclosures within an existing space, thus eliminating many of the costs and difficult decisions that are associated with redesigning, retrofitting, circumventing, or reintegrating a newer, more capable HVAC system.

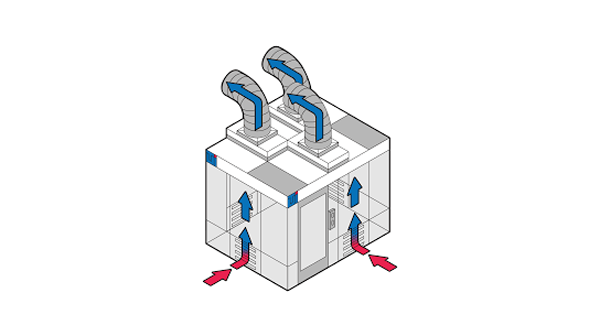

Standalone Exhaust Modules can be calibrated and ducted independently from existing systems, which can prevent issues with inefficient airflow or strain on facility-wide systems. Similarly, these systems allow for direct exhaust to an outdoor environment, which ensures short duct paths and easier calibration of minimum static pressure. Static pressure that is too low can mean that there isn't enough air being pushed through the system, which leads to inefficient heating or cooling and poor performance.

Isolator & Flow Hood Optimization: Terra evaluates potential energy savings concerning equipment selection and placement. For example, certain isolators may offer 30-50% energy savings compared to Restricted Access Barrier Systems (RABS) in HVAC systems used in filling suites.

Closed Loop Designs

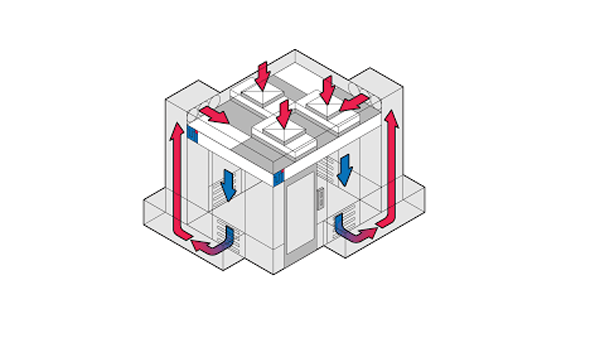

Closed-loop, recirculating designs use floor-level vents and plenums to recycle and refilter air back through the cleanroom for improved climate control and increased efficiency.

Positive Pressure Rooms

Positive pressure design including cascading pressure suites for maintaining room-to-room pressure values between rooms of divergent air flow and air quality.

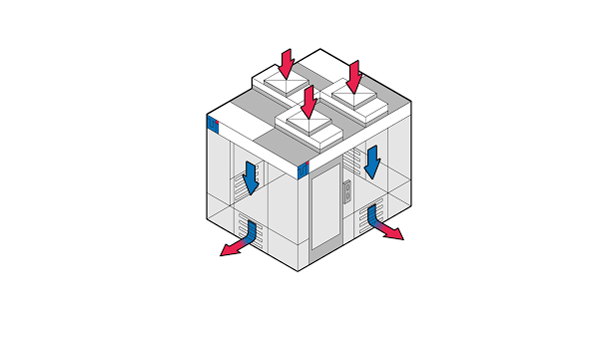

Negative Pressure Rooms

Terra's negative pressure containment rooms are configurable for direct exhaust to an outside environment or a dedicated air handling system.

Airflow Engineering

Design of interstitial cleanroom spaces including plenums, air returns, ducting, and exhaust systems for negative or positive pressure.

Modular Integration for New and Existing Builds

When designing enclosures for precise temperature and humidity control, the system performance will be heavily affected by exterior changes in the environment. To mitigate these variables, temperature control cleanrooms will require special attention to the integrity of the room or enclosure.

Smart® Fan Filter Power & Control Panels centralize control over assignable groups or specific targets when conducting cleanroom pressure-balancing, troubleshooting, or maintenance. These UL-Listed Smart Control Panels allow programmable fan speed adjustment, remote shutdown, and integrated displays of humidity, differential pressure, and temperature sensors.

Advanced Pass-Through Systems: Terra offers several pass-through models with integrated HEPA filters and blowers. Importantly, these systems are configurable as once-through (single pass) air supply systems, or as internally recirculating versions. In lab and compounding environments, recirculating systems minimize the disruption of differential pressure and reduce makeup air requirements, therefore improving overall efficiency.

Airlocks: Terra's personnel airlocks consist of two or more doors with interlocking mechanisms that prevent both doors from being open at the same time. This design helps to maintain the positive pressure of the cleanroom, ensuring that air is not lost from the cleanroom when personnel enter or exit.

Hybrid BioSafe® Modular Cleanrooms

Terra's Hybrid Modular Rooms are both flexible and scalable, accommodating a variety of utility connections including compressed gas, vacuum, plumbing, phone, and Ethernet lines. This flexibility ensures that the wall systems can be tailored to specific operational needs, making them suitable for a wide range of cleanroom applications. Hybrid design includes interlocking honeycomb wall panels lined with a uPVC substrate on the interior and exterior. Extruded aluminum side pieces allow each panel to interlock, with the gaps filled in with silicone sealant.

Turn-Key Cleanrooms

Modular, hybrid, and stick-built construction. Choose from an array of prefab, ready-to-ship systems. Or get a custom quote.

Smart® Fan Filter Units

Integral MODBUS® network cards for streamlining remote monitoring or IBMS integration connection with your existing systems.

HVAC Controllers

Terra's central control panels allow blower speed adjustment, diagnostics, energy-saving modes, and Wi-Fi-ready models.

HVAC Modules

Terra manufactures innumerable cleanroom HVAC systems including fan filter units, plenums, air returns, and climate control modules

End to End Cleanroom Design & Construction

Terra's customers benefit from substantial improvements in design methodologies, which stem from insights gleaned in high-performance ISO 5 — ISO 7 cleanroom builds spanning pharmaceutical, semiconductor, and the manufacturing of advanced medicinal therapies.

Architecture & Lab Planning

Terra offers full service packages for the design of large-scale facilities featuring multiple suites, offices, gowning rooms, mezzanines, and cleanroom spaces. For labs and cleanrooms, we provide comprehensive end-to-end outfitting solutions, including full furniture installations and meticulous planning of process flows that optimize the movement of people and products between clean and dirty zones.

Commissioning & Validation Services

Terra's cleanroom testing and certification services are designed to ensure the optimal performance of cleanroom filtration systems, clean air benches, laminar flow hoods, and other airflow-reliant systems. Our comprehensive certifications include airborne particle counts to assess the cleanliness level, HEPA filter velocity, and leak scans to ensure filter integrity, along with temperature and humidity checks for environmental stability.

Consulting & Expertise

Terra offers specialized pharmaceutical and healthcare consulting solutions with a track record of excellent in service of public and private sector agencies. We are committed to providing a quality consultation with a personal touch and modest fees. Our industry-leading experts comprise many years of expertise in areas such as pharmacy administration, pharmacy law and regulation, issues management, risk management, modeling of healthcare delivery, and patient safety/quality improvement.

Services & Solutions Overview

Terra deploys architects, engineers, and subject-matter experts to ensure the alignment of aesthetic appeal, facility integration, and floor planning with respect to multi-functional spaces.

Get a Cleanroom Consultation

Terra offers fully integrated cleanroom engineering design, architecture, construction, and system integration. Rest assured, you'll have a single point of contact for delivering a complete solution.

Ask a Terra Cleanroom Specialist

Shop Cleanrooms

Terra Universal designs, builds, and manufacturers over 500 cleanrooms annually and provides a wide range of services and equipment. Browse dozens of in-stock, prefab cleanroom models or submit a quote for custom solutions.

Contact Terra Universal

Sales and General Contact

Phone: +1 (714) 578-6100

Fax: (714) 578-6020

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Email: info@terrauniversal.com

Request a Quick Quote

Submit a QuickQuote request and a Terra application specialist will provide a quotation within 24 business hours. For immediate assistance from a Terra Product Specialist, start a web chat online or call (714) 578-6100

.jpg)

.png)

.png)