Terra Universal Cleanrooms

As a pioneer in the critical environment industry, Terra Universal has developed and manufactured innovative solutions for over 45 years. Combining high-throughput, automated fabrication equipment with a robust, active stock of raw materials, Terra is capable of producing cleanrooms of any design, size, scope, and complexity at industry-leading build times.

Long-Standing Reputation

Since 1976, Terra has successfully designed, manufactured, and installed thousands of cleanrooms worldwide for customers in the pharmaceutical, biomedical, life science, aerospace, and semiconductor industries. Terra’s customers include some of the largest research and production facilities across the globe.

Terra builds and installs over 500 cleanrooms per year, on average. All cleanroom components are pre-engineered, quality control tested, and stocked for quick integration and assembly.

Over 2,000 completed projects since 2017

- Multi-building, high-capacity manufacturing line

- Main campus located in Southern California

- Over 30 global partners

End-to-End Services

Terra offers integrated engineering, architectural design, and specialized consulting services to ensure cohesive alignment of aesthetic considerations, facility infrastructure, and spatial planning for multi-functional cleanroom environments. These end-to-end solutions support seamless integration with existing systems while addressing the unique demands of each application.

Hybrid Stick-Built / Modular Rooms

Terra's modular cleanroom panels arrive from the factory with prespecified cutouts for pass-throughs, doors, and windows, which eliminates most on-site modifications that would otherwise require sawing, cutting, or drilling. Terra offers innumerable options for component integration including filter fan units, lights, power distribution modules, control panels, doors, windows, and pass-through chambers stocked and ready for immediate shipment

Built to Your Standards

Terra offers a wide range of value-add services, including white glove delivery, cleanroom installation, structural seismic analysis, expedited production, qualification documentation, and extended warranties. Order-specific certificates of compliance, listing each product’s adherence to ISO, UL, OSHA, and seismic standards, are supplied with every qualifying sale.

Semiconductors

Hitachi Global

Lexmark Intl.

KLA-Tencor

Intel

IBM

Samsung

Hewlett Packard

GE

Qualcomm

Triquint

Aerospace

Boeing

Lockheed Martin

Rockwell Collins, Inc.

Raytheon Systems

JPL

SpaceX

Northrop Grumman

Lawrence Livermore

Sandia National Labs

Teledyne

Medical/Hospital

Kaiser Permanente

Mountain State Health

National Institutes of Health

VA Hospitals

Cardinal Health

St. Jude Medical

Carestream Health

Providence Health System

Baylor Health Care System

Mayo Clinic

Medical Device

Siemens Health Care

Bacterin International

OPKO Diagnostics

Medtronic, Inc.

Abbott Labs

Covidien/Tyco Healthcare

Cameron Health

GE Healthcare

Ethicon, Inc.

Boston Scientific

Biotechnology

Millipore Corporation

Genzyme Corporation

Organogenesis, Inc.

Meridian Bioscience

Affymetrix, Inc.

Celgard, LLC

Life Technologies

Becton Dickinson

MedImmune, Inc.

Alcon Labs

Pharmaceutical

Pfizer, Inc.

Genentech

Baxter Healthcare

Amgen, Inc.

Teva Pharmaceuticals

Merck

GlaxoSmithKline

Johnson & Johnson

Watson Labs

Gilead

Universities

Kaiser Permanente

Mountain State Health

National Institutes of Health

VA Hospitals

Cardinal Health

St. Jude Medical

Carestream Health

Providence Health System

Baylor Health Care System

Mayo Clinic

Other Key Clients

Siemens Health Care

Bacterin International

OPKO Diagnostics

Medtronic, Inc.

Abbott Labs

Covidien/Tyco Healthcare

Cameron Health

GE Healthcare

Ethicon, Inc.

Boston Scientific

Terra Construction Capabilities

Terra's process includes defining project scope, designing cleanrooms, and engineering with in-house teams and partners. Manufacturing occurs at their California campus, with quality-tested components and efficient production. Procurement leverages a wide supplier network, ensuring cost-effective deliveries. Logistics coordinate for timely delivery and installation, with specialized services available. Pre-validation tests ensure cleanroom performance, and Terra offers comprehensive maintenance services.

1. Cleanroom Design & Scope

Terra's process includes defining project scope, designing cleanrooms, and engineering with in-house teams and partners. Manufacturing occurs at their California campus, with quality-tested components and efficient production. Procurement leverages a wide supplier network, ensuring cost-effective deliveries. Logistics coordinate for timely delivery and installation, with specialized services available. Pre-validation tests ensure cleanroom performance, and Terra offers comprehensive maintenance services.

2. Engineering

In the initial design stages, Terra works to align the cleanroom's preliminary and detailed designs with the end-user's specifications and prevailing industry norms. This involves the selection and integration of suitable materials, HVAC configurations, filtration systems, and spatial planning to render a final design that meets the essential requirements.

3. Manufacturing and Construction

After project release, Terra manufactures many of its modular cleanroom components in house, including wall panels, ceilings, filter fan units, doors, pass-through chambers, furniture, and more at our 350,000 square foot manufacturing campus in Southern California. All cleanroom components are manufactured using high-precision fabrication machinery, tested to ensure quality, performance guaranteed, and delivered on time to the construction site. No matter the scale of the project, Terra’s high-capacity production lines are capable of industry-leading build times.

4. Procurement

Leveraging Terra’s network of over 80 major suppliers and vendors, our project management team coordinates with project stakeholders to ensure cost savings and timely delivery of value-add products from brands like Labconco, Thermo Fisher, Metro, Eagle, Biofit, Rubbermaid, Germfree and more.

5. Shipping, Installation, and Logistics

Terra’s logistics team coordinates with vendors, suppliers and project stakeholders to ensure consolidated, timely delivery of the cleanroom, and all associated equipment, to the construction site. Specialty freight services, such as white glove delivery, overnight shipping, and weekend deliveries are available. Terra’s experienced, skilled installation team executes zone-build methodology, coordinates with specialty tradesmen, performs on-site validation, and handles equipment move-in.

6. Cleanroom Start-Up Validation

During cleanroom pre-certification and pre-validation, Terra’s engineers perform an array of tests to ensure the cleanroom operates according to design objectives and specifications, including air balancing, particulate counts, atmospheric control, air changes and pressurization. If required, equipment validation and testing, such as IQ, OQ and PQ, is performed and submitted prior to close-out inspection.

Get a Cleanroom Consultation

The next-generation of cleanrooms: hybrid cleanrooms modular components, stick-built design freedom, and BioSafe® characteristics for uncompromising cleanroom builds.

Ask a Terra Cleanroom Specialist

Modular Hardwall

Terra’s hardwall modular cleanrooms provide a completely enclosed, rigid freestanding structure with positive-pressure air exhaust vents.

Modular Softwall

Terra’s modular softwall cleanrooms feature strip-shield curtains, ASTM-rated powder-coated frames, and portable configurations with mobile casters

Traditional Stick-Built

Built-to-order designs for life science applications, such as bio/pharmaceutical applications that require a clean, sterile environment

All-Steel BioSafe®

Terra's All-Steel Pharmaceutical Cleanrooms include double-wall, all-steel, gapless panels that minimize cracks, gaps, and crevices where germs collect and colonize.

Browse Terra Cleanroom Components

Fan Filter Units

Terra’s WhisperFlow Fan Filter Units provide a uniform flow of micro-filtered air to meet cleanliness standards down to Class 10/ISO4.

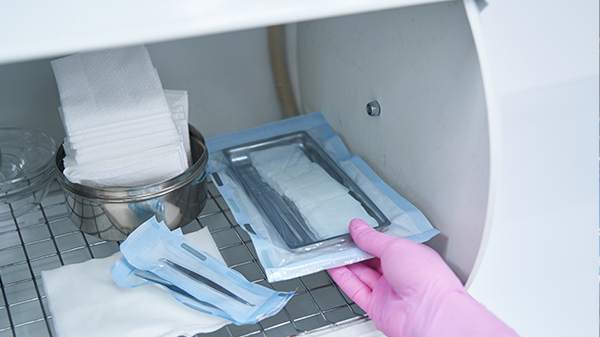

Pass-Throughs

Styles include BioSafe®, Smart® enabled, refrigerated, HEPA/ULPA recirculating, roll-up doors, cart transfer, sliding windows, and more

Control Panels

Compare control systems for FFUs with on/off controls, power saving modes, filter replacement alarms, and more.

Lights & Panels

LED panels mount flush on ceiling grid, have longer life, and use less energy (emitting less heat) than conventional fluorescent lights.

Shop Cleanrooms

Terra Universal designs, builds, and manufacturers over 500 cleanrooms annually and provides a wide range of services and equipment. Browse dozens of in-stock, prefab cleanroom models or submit a quote for custom solutions.

Contact Terra Universal

Sales and General Contact

Phone: +1 (714) 578-6100

Fax: (714) 578-6020

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Email: info@terrauniversal.com

Request a Quick Quote

Submit a QuickQuote request and a Terra application specialist will provide a quotation within 24 business hours. For immediate assistance from a Terra Product Specialist, start a web chat online or call (714) 578-6100